If you are changing for "wear" then there are wear indicators, for checking both the sets involved, the side pads, and the front with back shells.

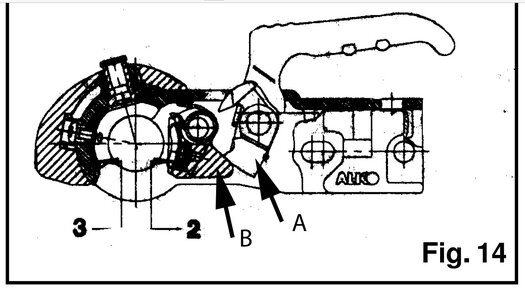

The side pad wear is indicated on the bosses at the base of the big Black, [ in your case], pad loading lever. If you are mega keen, the handle can be removed to check the individual wears, port & starboard.

The front & rear set indicator is via little red green plastic pieces, at the base of the ball release handle.

Changing the former is an easier quicker task than changing the front & rear set.

Google search for the specifics.

Edit: Found one bit for you.

LINK

-------------------------

It would be a surprise to me if you have travelled far enough to have worn either sets out, looked after we are talking 30K plus towed miles in my experience; way the more likely is the side pads are "grubby" and or glazed, these can be cleaned & de-glazed with course "sandpaper" and brake pad cleaner fluid.

I find it way easier to remove the whole assembly for the front and rear pad change and do it on a bench, than get my aging body in place to work upside down inside the hitch. A lot less chance of screwing it up if you can see what you are doing, but then it is also tempting at 30K miles to strip the lot and properly "service" the assembly.