Hi,

I've collected a Coachman 420/2 year 2007 which my son has bought for us to use whilst we are visiting.

It has a Reich "Move Control" motor mover model 527-0521 dating from 2003 according to the label on the control box. It's probably an early model with a small oblong black handset with 7 red buttons on the front. The handset switches on and off no problem and the LED lights up when it's on.

When i tested the device not attached to the wheels, the motors moved smoothly.

But when I clamped the mover onto the van tyres, the van moved for a couple of yards, then the mover stopped working. Yes I had taken off the handbrake..... and the van battery is 100% charged and I have replaced the battery in the control box.

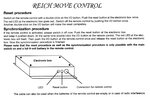

I'm assuming it's either a fuse or a reset button, but I cannot find the location of either.

No copy of the manual available on the internet that I can find.

If anyone can suggest a solution, I'd be very grateful.

Thanks

I've collected a Coachman 420/2 year 2007 which my son has bought for us to use whilst we are visiting.

It has a Reich "Move Control" motor mover model 527-0521 dating from 2003 according to the label on the control box. It's probably an early model with a small oblong black handset with 7 red buttons on the front. The handset switches on and off no problem and the LED lights up when it's on.

When i tested the device not attached to the wheels, the motors moved smoothly.

But when I clamped the mover onto the van tyres, the van moved for a couple of yards, then the mover stopped working. Yes I had taken off the handbrake..... and the van battery is 100% charged and I have replaced the battery in the control box.

I'm assuming it's either a fuse or a reset button, but I cannot find the location of either.

No copy of the manual available on the internet that I can find.

If anyone can suggest a solution, I'd be very grateful.

Thanks