Caravan Jack

- Thread starter RayR

- Start date

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

- Nov 11, 2009

- 26,034

- 9,659

- 50,935

I used a hydraulic bottle jack but also had a Alko side lift jack that engaged in the Alko chassis mounted lifting brackets. The bottle was preferable as it could be positioned right under the axle adjacent to the wheel.

Don’t forget that after changing a wheel to retorque after 25-50 miles. Also when fitting a steel spare it will have a different torque to the OEM alloys. If you have an owners manual that should give the figure. Sometimes it is printed on the information label/plate near the door.

Don’t forget that after changing a wheel to retorque after 25-50 miles. Also when fitting a steel spare it will have a different torque to the OEM alloys. If you have an owners manual that should give the figure. Sometimes it is printed on the information label/plate near the door.

Last edited:

- Nov 30, 2022

- 2,021

- 1,930

- 5,935

There is specific jack, along with brackets for Bailey's. DONT ever jack on just tge chassis rail, it will bend and break the galvanising. If you don't have/don't want the purpose built brackets and jack then I would advise you get a low profile trolley jack so you can get it under the axle as close to the wheel as possible. A bottle jack is fine until you get a flat tyre, at which point it's too tall to fit underneath any other than the chassis rail (see above!)

As for wheel nut size, check tgey are all a standard hexagonal nut, my Bailey (2019) has WSL nuts that need a specific tool and cannot be undone with a standard socket. Earlier ones had a single WSL as an anti theft measure.

As for wheel nut size, check tgey are all a standard hexagonal nut, my Bailey (2019) has WSL nuts that need a specific tool and cannot be undone with a standard socket. Earlier ones had a single WSL as an anti theft measure.

- Nov 11, 2009

- 26,034

- 9,659

- 50,935

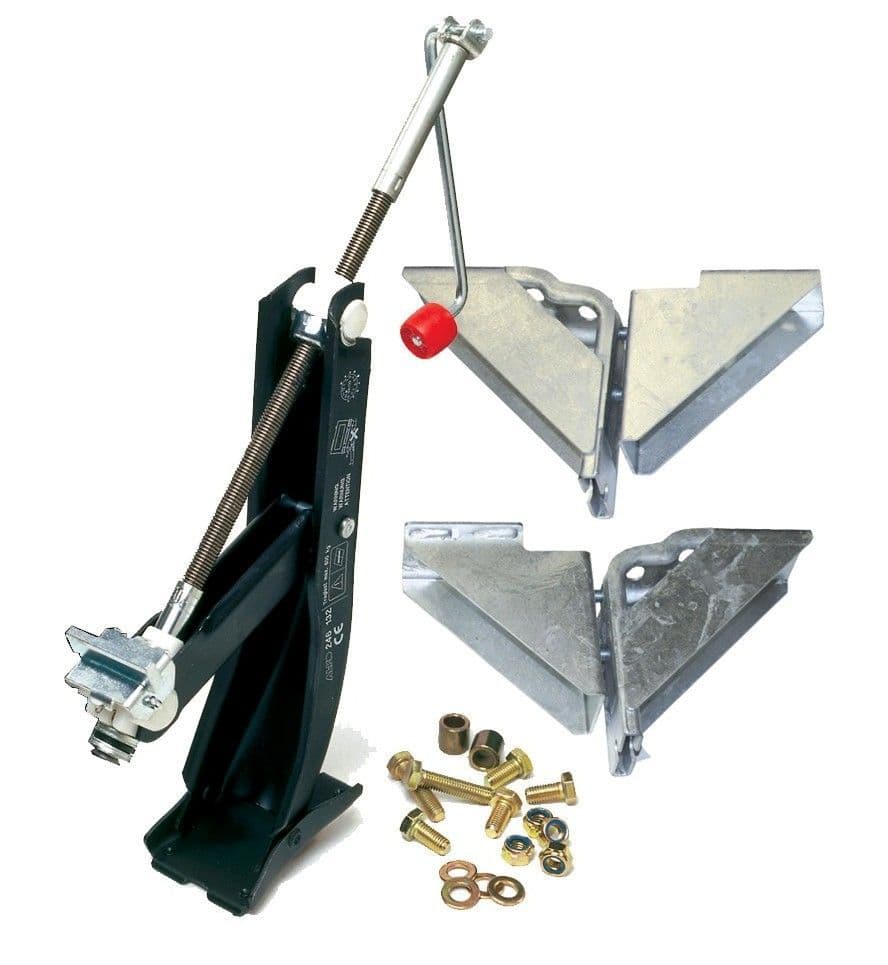

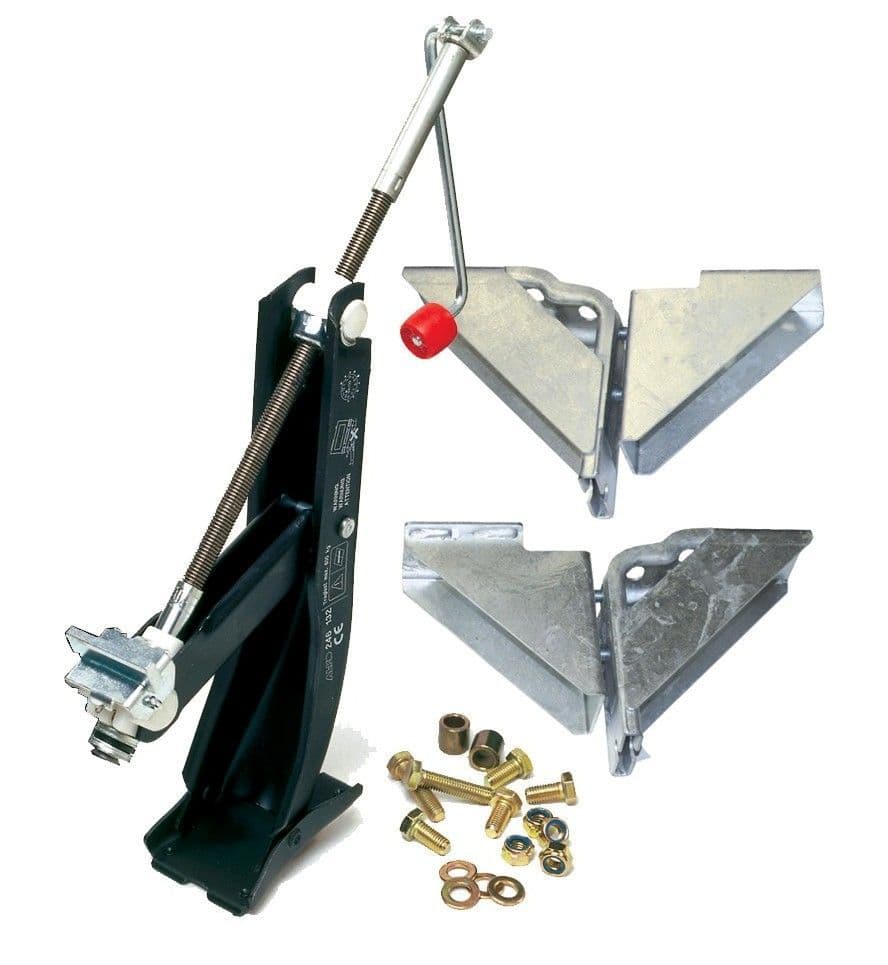

Here’s a link showing the Alko Jack and brackets. There are two designs of bracket dependent on the max weight of the caravan. The weight shown at the link is per wheel.

Alko website shows details too.

www.tauntontrailers.co.uk

www.tauntontrailers.co.uk

Alko website shows details too.

AL-KO JACK KIT 1000KG - 2000KG 1389235

Genuine Al-ko replacement side lift jack kit up to 2000kgs Kit comprises of side lift jack plus two pairs of galvanised steel brackets, associated

- Jun 20, 2005

- 20,430

- 5,581

- 50,935

After years of trials with useless jacks eg Al-ko side lift, I use the reinforced Purple line triangular chassis brackets ( the new Al-ko brackets are similar) with an original 3 stage Kia Sorento Mk1 hydraulic bottle jack. It is low enough to fit after a flat and rises more than enough to change the wheel. Stable too. Go online to the breakers yards and you can get the jack and handle for £30/40. Most of them have never been used!

- Jul 15, 2008

- 3,939

- 1,140

- 20,935

..........If you don't have/don't want the purpose built brackets and jack then I would advise you get a low profile trolley jack so you can get it under the axle as close to the wheel as possible.

https://forums.practicalcaravan.com/threads/caravan-jacking.63985/post-544093

IMO.....a bottle jack is best for lifting a caravan.

Most caravanners carry ramps so in the event of a caravan flat tyre that tyre can be hauled up a ramp to obtain the necessary clearance for the bottle jack.

- Nov 11, 2009

- 26,034

- 9,659

- 50,935

Agreed, and if your spare wheel is carried on the Alko under slung wheel carrier ( terrible piece of kit) you do have to drive up one of the ramps as trying to withdraw the wheel carrier when the van is on a jack is a safety hazard.https://forums.practicalcaravan.com/threads/caravan-jacking.63985/post-544093

IMO.....a bottle jack is best for lifting a caravan.

Most caravanners carry ramps so in the event of a caravan flat tyre that tyre can be hauled up a ramp to obtain the necessary clearance for the bottle jack.

That's standard advice but every AWS technician and mobile tyre fitter I've used has done just that.DONT ever jack on just tge chassis rail, it will bend and break the galvanising.

- Nov 16, 2015

- 12,695

- 4,839

- 40,935

My AWS tech does the same, but he has a rubber block between the Jack and the chassis rail.That's standard advice but every AWS technician and mobile tyre fitter I've used has done just that.

- Jun 20, 2005

- 20,430

- 5,581

- 50,935

It’s called GSI! Get Someone In🤪On the occasiosn when the technician has had to change a caravan tyre, they have used either a bottle jack or hydraulic jack under the axle. Luckily now if we need a wheel change we do not require a jack.

- Jul 18, 2017

- 16,925

- 5,505

- 50,935

- Jul 18, 2017

- 16,925

- 5,505

- 50,935

It replaces the front and rear steadies and has jacks in the centre to raise the wheels. Standard fit on our caravan.The E and P system, where does it attach to the van , we are told don't try and jack your caravan with the Steady stays, which I agree with. So the E&P system must have extra support,? How is it done.

I made the mistake in getting a trolley jack. The problem was that it was only a 2 tonn (2000 kilo) Trolley Jack and full the caravan weighed 1575 and with the trolley jack pushed underneath the axle the jack lever was still quite a way underneath the caravan and it took an enormous effort to push down the 2 inches of travel to lift it. So I bought a 7.5 Tonn Bottle Jack for about £15 off eBay and its very good.There is specific jack, along with brackets for Bailey's. DONT ever jack on just tge chassis rail, it will bend and break the galvanising. If you don't have/don't want the purpose built brackets and jack then I would advise you get a low profile trolley jack so you can get it under the axle as close to the wheel as possible. A bottle jack is fine until you get a flat tyre, at which point it's too tall to fit underneath any other than the chassis rail (see above!)

As for wheel nut size, check tgey are all a standard hexagonal nut, my Bailey (2019) has WSL nuts that need a specific tool and cannot be undone with a standard socket. Earlier ones had a single WSL as an anti theft measure.

I just bought a scissor jack havn't tried to actually jack up the van yet but i put it under there and i think it will work OK. Hopefuly never need it

Thanks for all your replies

Ray

Thanks for all your replies

Ray

- Nov 16, 2015

- 12,695

- 4,839

- 40,935

I have a Kojack Hydraulic scissor jack, with the dedicated bolt on jacking points to fit behind the wheels of a single axle caravan. My Coachman came with almost identical jacking points. The early Kojack Hydraulic units had problems leaking, mine has been fine , I carry it in the. Car for use, Just in case.

TRENDING THREADS

-

-

-

Mandatory eye tests for drivers over 70 being proposed by HMG. Good or bad?

- Started by Dustydog

- Replies: 197

-

-

-

-

Practical Caravan is part of Future plc, an international media group and leading digital publisher. Visit our corporate site.

© Future Publishing Limited Quay House, The Ambury, Bath BA1 1UA. All rights reserved. England and Wales company registration number 2008885.