Hello to the collective wisdom!

I've bought a S/H set of Evolution single / manual movers (I like a challenge) and have been testing in the shed prior to fitting. They're 10 years old with an FM transmitter. A brand new 105Ah battery is powering proceedings.

A couple of odd things have happened and I'd love a bit of guidance before I go too much further, please.

1. One side runs faster than the other, say about 15%. It's NOT the wire length, I believe, although they have been cut. If I swap the connectors over the same motor still runs slower (both directly forward and back). It is definitely more sluggish to start and then seems to lag increasingly on the revolutions, judging by my marker pen lines. I'm certainly thinking the issue is at the motor end. Maybe the brushes?

2. If I try to go forward diagonal right on the handset, one side switches into reverse! This could cause an expensive pirouette... This one seems more likely to be the electronics (?), probably the remote (which looks well thumbed) but maybe the control box. Any ideas?

and lastly a little one:

3. Everything is there except the plastic cable retainer is missing from the inboard side of one drive unit. How important are these, really? I expect I can improvise something.

Many thanks in advance

PS The grub screws were also not there but I understand they are not strictly needed for single axle units.

I've bought a S/H set of Evolution single / manual movers (I like a challenge) and have been testing in the shed prior to fitting. They're 10 years old with an FM transmitter. A brand new 105Ah battery is powering proceedings.

A couple of odd things have happened and I'd love a bit of guidance before I go too much further, please.

1. One side runs faster than the other, say about 15%. It's NOT the wire length, I believe, although they have been cut. If I swap the connectors over the same motor still runs slower (both directly forward and back). It is definitely more sluggish to start and then seems to lag increasingly on the revolutions, judging by my marker pen lines. I'm certainly thinking the issue is at the motor end. Maybe the brushes?

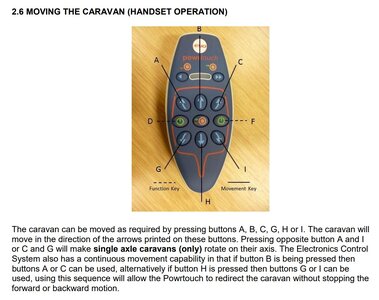

2. If I try to go forward diagonal right on the handset, one side switches into reverse! This could cause an expensive pirouette... This one seems more likely to be the electronics (?), probably the remote (which looks well thumbed) but maybe the control box. Any ideas?

and lastly a little one:

3. Everything is there except the plastic cable retainer is missing from the inboard side of one drive unit. How important are these, really? I expect I can improvise something.

Many thanks in advance

PS The grub screws were also not there but I understand they are not strictly needed for single axle units.