Zinc-plated wheel bolts

Page 2 - Passionate about caravans & motorhome? Join our community to share that passion with a global audience!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

- Jun 20, 2005

- 20,441

- 5,587

- 50,935

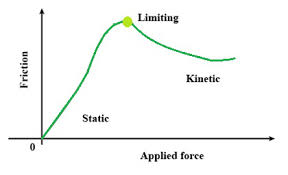

Prof ,There are several factors at play here some may allow the fastener to relax a little as the compressed materials settle, and other mean once the fixing has torqued, to move it any more requires several percent more torque to over come the static limiting friction to actually get the fastener rotating

In the context of wheel fasteners these differences are insignificant and we can in practice ignore them. and checking the torque settings should make no practical difference to the safety or effectiveness of the fasteners.

A real master piece ! Thankyou.

This evening discussed to death with one of my friends who was an RAF air frame engineer for 25 years. He says exactly the same . On the aircraft , assuming the threads are fully clean only one torque up is required. None of this check and check again nor after so many minutes or miles. We thrashed it out for quite a while. As he said do you remember any aircraft crashing because of failure to check the torque.

Going forward I will not be doing anything. Strange , I never bothered with the car!

So why do so many “experts” tell you to check the torque after 50 miles?

Generally because wheels can have a habit of falling off caravans but not off of cars or aircraft 🤔

Manufactures don’t balance wheels so there is another added factor…shaking the van to bits.

I don’t think that caravans go through the same processes as aircraft where everything is signed off a hundred times before it can move either 🤔

Manufactures don’t balance wheels so there is another added factor…shaking the van to bits.

I don’t think that caravans go through the same processes as aircraft where everything is signed off a hundred times before it can move either 🤔

- Jun 20, 2005

- 20,441

- 5,587

- 50,935

For 40 + years all my caravan wheels are rebalance after a tyre change.Mandatory in my book !Generally because wheels can have a habit of falling off caravans but not off of cars or aircraft 🤔

Manufactures don’t balance wheels so there is another added factor…shaking the van to bits.

I don’t think that caravans go through the same processes as aircraft where everything is signed off a hundred times before it can move either 🤔

I agree it’s the 3-7 years prior that can cause an issue 🤔For 40 + years all my caravan wheels are rebalance after a tyre change.Mandatory in my book !

- Nov 11, 2009

- 26,052

- 9,672

- 50,935

- Mar 14, 2005

- 19,278

- 4,473

- 50,935

Firstly Dusty, It may not have come across clearly from my last post, but I'm not advocating no secondary checking, only that if you do check the torque its not going cause the applied torque to rise unduly if at all.

As to the need to check the wheel torque after some distance or before every journey, as it does no harm. As Roger has intimated, there is a history pointing to an unreasonable number of caravan wheels coming loose.

This either means the fasteners worked loose, or the metal flanges being clamped was prevented from making full metal to metal contact by contamination, which when subject to teh dynamic forces of being towed and the mass of the caravan caused the contamination to be ejected or worn away reducing the clamping force and allowing the fasteners to work loose.

There is still no confirmed reason for why the fastenings work loose, but undoubtedly its belt and braces to make torque checks a pre flight check and if nothing else it can bring peace of mind.

As to the need to check the wheel torque after some distance or before every journey, as it does no harm. As Roger has intimated, there is a history pointing to an unreasonable number of caravan wheels coming loose.

This either means the fasteners worked loose, or the metal flanges being clamped was prevented from making full metal to metal contact by contamination, which when subject to teh dynamic forces of being towed and the mass of the caravan caused the contamination to be ejected or worn away reducing the clamping force and allowing the fasteners to work loose.

There is still no confirmed reason for why the fastenings work loose, but undoubtedly its belt and braces to make torque checks a pre flight check and if nothing else it can bring peace of mind.

Last edited:

- Jun 16, 2020

- 5,904

- 2,810

- 17,935

Add to your list what I posted in #9 regarding undersized bolts in the UK. Why are UK bolts smaller than Continental on Alko chassis?Firstly Dusty, It may not have come across clearly from my last post, but I'm not advocating no secondary checking, only that if you do check the torque its not going cause the applied torque to rise unduly if at all.

As to the need to check the wheel torque after some distance or before every journey, as it does no harm. As Roger has intimated, there is a history pointing to an unreasonable number of caravan wheels coming loose.

This either means the fasteners worked loose, or the metal flanges being clamped was prevented from making full metal to metal contact by contamination, which when subject to teh dynamic forces of being towed and the mass of the caravan caused the contamination to be ejected or worn away reducing the clamping force and allowing the fasteners to work loose.

There is still no confirmed reason for why the fastenings work loose, but undoubtedly its belt and braces to make torque checks a pre flight check and if nothing else it can bring peace of mind.

I have been told that smaller bolt diameters give manufacturers more freedom to choose aesthetically prettier wheels.

Perhaps that is true.

John

Are the bolts smaller - or is the hexagon head smaller? UK caravans seem to use M12 (12mm) bolts with a 19mm hexagonal head - it's possible to get M12 bolts with a 17mm hexagonal head.Add to your list what I posted in #9 regarding undersized bolts in the UK. Why are UK bolts smaller than Continental on Alko chassis?

I have been told that smaller bolt diameters give manufacturers more freedom to choose aesthetically prettier wheels.

Perhaps that is true.

John

As an update to my OP, it seems that some workshops have been fitting these low-friction replacement bolts for years, over 10 years in one case, but without any publicity and insisting that replacement is done by trained technician, not DIY. I want to know why the industry is so secretive on this issue.

Last edited:

They are generally same thread and 17mm head as you say 👍Are the bolts smaller - or is the hexagon head smaller? UK caravans seem to use M12 (12mm) bolts with a 19mm hexagonal head - it's possible to get M12 bolts with a 17mm hexagonal head.

.

- Jun 20, 2005

- 20,441

- 5,587

- 50,935

As I said earlier this issue came to a head 12 years ago but seemed limited to Bailey Unicorns.

This link explains exactly what happened and the solution. Why Roger’s chaps have raised it again , now is a mystery. Has something else happened that we don’t know about?

I will still check the bolts as before , clearly it does no harm and as the apron said it will not cause the torque to rise if at all.

https://www.caravanclub.co.uk/media/7980301/ccmoctspecwheels.pdf

This link explains exactly what happened and the solution. Why Roger’s chaps have raised it again , now is a mystery. Has something else happened that we don’t know about?

I will still check the bolts as before , clearly it does no harm and as the apron said it will not cause the torque to rise if at all.

https://www.caravanclub.co.uk/media/7980301/ccmoctspecwheels.pdf

That Caravan Club report does end with the comment "The NCC, through its TechnicalAs I said earlier this issue came to a head 12 years ago but seemed limited to Bailey Unicorns.

This link explains exactly what happened and the solution. Why Roger’s chaps have raised it again , now is a mystery. Has something else happened that we don’t know about?

I will still check the bolts as before , clearly it does no harm and as the apron said it will not cause the torque to rise if at all.

https://www.caravanclub.co.uk/media/7980301/ccmoctspecwheels.pdf

Committee, is now examining the findings to determine whether there are any longer term implications for the industry as a whole" so I wonder if this is the result - doesn't explain the secrecy though

- Jun 16, 2020

- 5,904

- 2,810

- 17,935

I don’t know the head hex size, but the bolts are M14 on continental vans, the extra frictional grip has to be verysignificant.Are the bolts smaller - or is the hexagon head smaller? UK caravans seem to use M12 (12mm) bolts with a 19mm hexagonal head - it's possible to get M12 bolts with a 17mm hexagonal head.

As an update to my OP, it seems that some workshops have been fitting these low-friction replacement bolts for years, over 10 years in one case, but without any publicity and insisting that replacement is done by trained technician, not DIY. I want to know why the industry is so secretive on this issue.

Alko have the hubs cast. The same hubs are then machined for 5 x M12 for the UK and 5 x M14 for everyone else.

I don’t know if there are statistics, but it appears that wheel detachments are more prevelent on UK vans.

Since discovering this, and having a detackement at 55mph, I do what I can do to minimise the risk. for me that is WSL bolts.

John

TRENDING THREADS

-

-

-

-

Mandatory eye tests for drivers over 70 being proposed by HMG. Good or bad?

- Started by Dustydog

- Replies: 201

-

-

-

Practical Caravan is part of Future plc, an international media group and leading digital publisher. Visit our corporate site.

© Future Publishing Limited Quay House, The Ambury, Bath BA1 1UA. All rights reserved. England and Wales company registration number 2008885.